DIGITALISIERTE OBJEKTPOSITIONEN

ERFASSUNG IN PHYSISCHEN UMGEBUNGEN

B2B-Tracking-Integration mit unserer Lösung

1. Einfache, planbare, dokumentierte Umsetzung

- Industrietaugliche Hard- und Software

- B2B-Lieferprozess für vorinstallierte Hardware

- Planung und Konfiguration innerhalb des Systems

- Tools und Prozesse für den dokumentierten Rollout

2. Lifecycle-Management für die Anforderungen von Unternehmen

- Vollständig dokumentierte Services

- Wartungsfreundlichkeit: konfigurierbares, überwachtes System

- B2B-Unterstützung auf verschiedenen Ebenen

3. Offene Datenlösung und einfache Integration

- verschiedene Datenschnittstellen und Endpunkte zum Empfangen und Senden von Daten

- "on-premise" verfügbar für volle Systemkontrolle

- SDK für mobile Geräte verfügbar

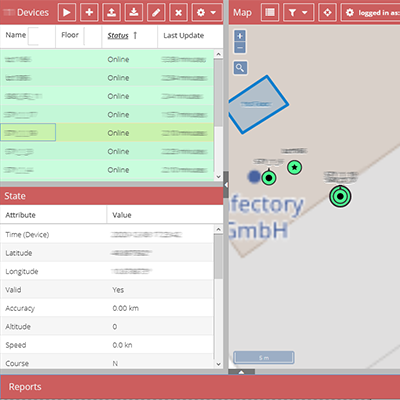

Backend / API

- Vor Ort oder per cloud

- Einfache Verwaltung

- Offene Daten

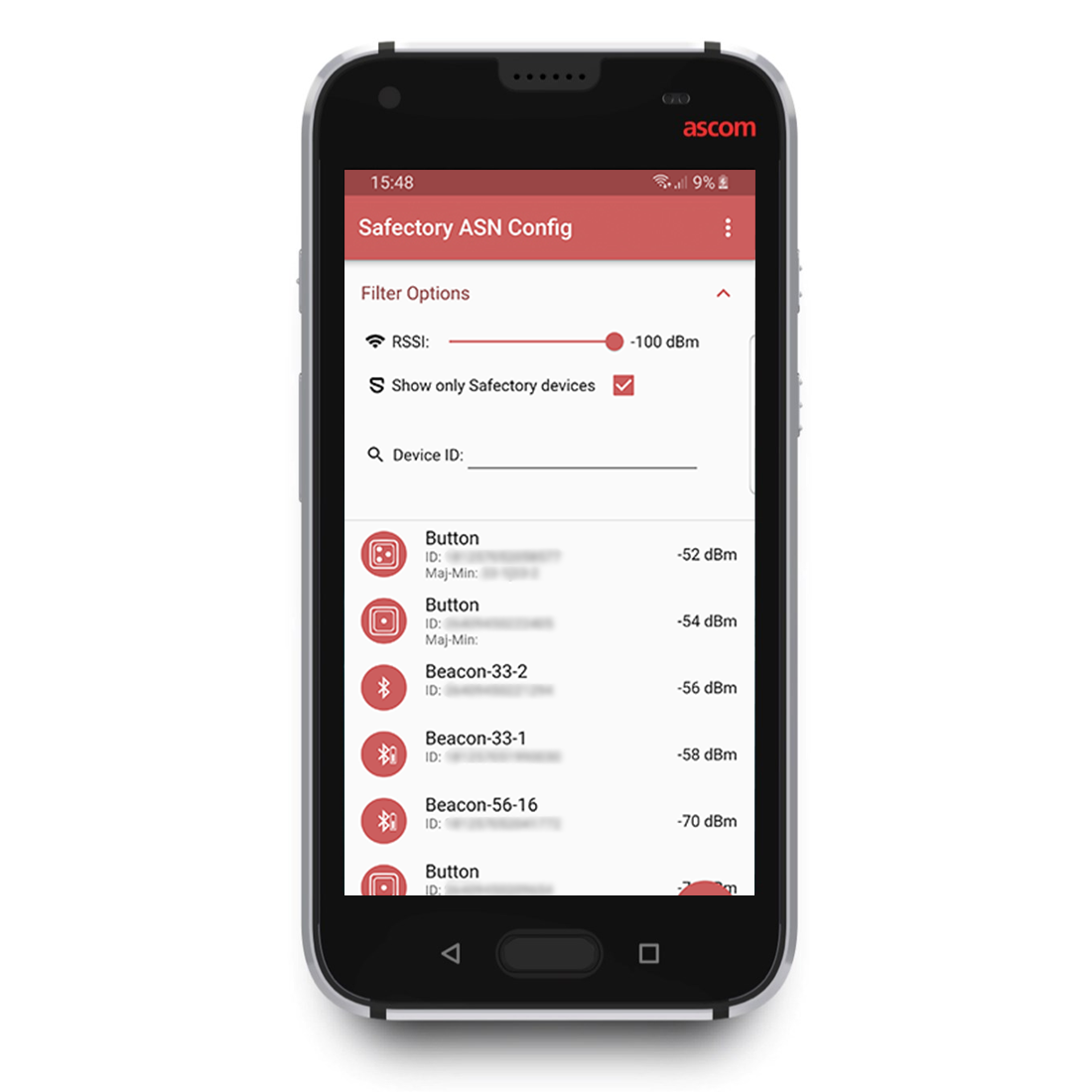

Config APP

- Prüfung und Documentation

- Vor-Ort Konfiguration

- Gesicherter Zugang